In search of the source of the stain–he was that bored–Petersen walked into the nearest lab. The stain, he found out, came from an ink spill. The lab was developing inkjet printer nozzles by etching precise holes in silicon.

Etching holes in silicon? It hadn’t ever occurred to Petersen that you could etch holes in silicon. Suddenly the bigger picture snapped into focus: People were actually building tiny mechanical gadgets, their parts just a few micrometers across, out of silicon.

Diving into the topic, he researched a report that became the cover story in The Proceedings of the IEEE in May 1982: “Silicon as a Mechanical Material,” that helped establish MEMS as its own branch of technology.

He touted silicon’s mechanical properties, calling it “a high-precision, high-strength, high-reliability mechanical material, especially applicable wherever miniaturized mechanical devices and components must be integrated or interfaced with electronics.”

There’s Plenty of Room at the Bottom

The theoretical underpinnings of MEMS began with a lecture given by physicist Richard Feynman at the annual American Physical Society meeting at Caltech on December 29, 1959: “There’s Plenty of Room at the Bottom: An Invitation to Enter a New Field of Physics.” Feynman considered the possibility of direct manipulation of individual atoms as a more powerful form of synthetic chemistry.

Today, Atomica’s MEMS have secured a foothold in today’s industrial and electronic world – and are poised to play even more crucial roles in tomorrow’s innovations.

The size, speed, reliability, and low cost of these miniature components serve a wide range of functions in an even wider array of applications. Their great value in fields such as 5G communications, IoT sensing, biochips, and autonomous vehicles will ensure exponential growth for the foreseeable future.

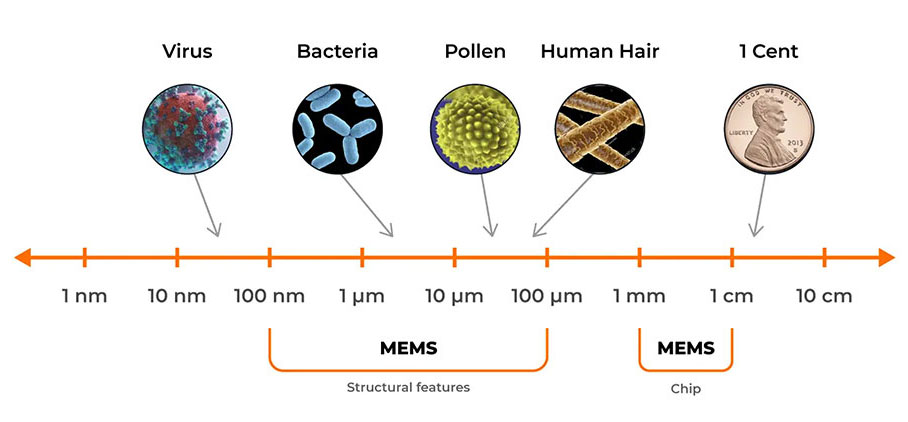

Size range of Atomica MEMS

Kinds of MEMS

Micropumps

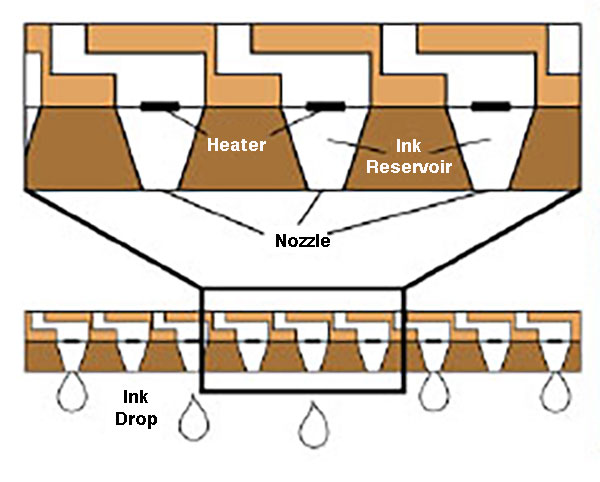

The inkjet was the earliest and most recognizable use of micropump technology. An empty cavity sits behind each of the nozzles in the print head. Ink flows into the cavity and, when heated by minuscule heating elements, is ejected from the nozzle onto the waiting paper.

Automated drug delivery systems also commonly employ micropumps.